1988

1990

1992

1994

1996

1998

2000

2002

2004

2006

2008

2010

2012

2014

2016

2018

loading...

____________

There is a ribbon of farmland that begins narrow at the foothills of a mountain range inching north like an arched and twisted spine. Here are the headwaters of the Missisquoi River, a clear north-bound tendril trickling by the gentler hills to the east, forming a valley that billows and stretches into sprawling plains at the Canadian border not ten miles away. In early fall, the valley’s hillsides turn a dusty purple as trees draw in chlorophyll from their limbs, and the forest floor is littered with red leaves peeking out through the tangled mesh of grey branches. Over the hill in another valley, corn fields mark the land like tufted squares on a beige rug, shorn in succession during the autumn months until the frost begins to collect on the corn tassels, and the snarling weeds in roadside ditches have blackened. By then, the fields are the deep brown of the dirt, gouged and strewn with mangled corn stalks.

But against this withering backdrop, the farmland of the Missisquoi River valley stays green with its seamless pastures, grasslands that swell and dip as though a blanket has been tossed over the bodies of sleeping giants. In the towns of Westfield and Troy, a cracked asphalt highway cuts by farmhouses more than a hundred years old, their white siding and black shingles unchanged, and the barns behind them, many red, some turquoise, some blue. Beyond the barns: small black and white splotches in a sea of green: dairy cows, pulling at the grass until their noses brush against the earth come autumn.

This is a scene pressed on the front of postcards stamped and mailed across the country to grandmothers and lovers for decades, kept on fridge doors or in a box at the back of a closet, a static image embodying the pastoral ideal that has come to define imaginations of rural Vermont. But while the footprint and colors of agriculture have not changed much in the century and a half since these fields were carved out of thick forest, this valley is anything but inert.

1988

1990

1992

1994

1996

1998

2000

2002

2004

2006

2008

2010

2012

2014

2016

2018

At 3:30, the cows amble across the fields under a sky thick with darkening clouds and into the barnyard. 50 black and white Holsteins, heads bobbing. They pause at the water tank, drinking in heaves, before going to huddle by the side of the barn where their noses push steam onto windows coated in a chunky film of dust. Inside the farmhouse, Lyle Edwards Jr. finishes a grilled cheese sandwich at the tiled kitchen counter, eyes the clock, and makes his way across the driveway and into the other end of the barn, a looming grey A-frame with bare wooden patches where shingles have sloughed off over the years. It’s time to bring the cows in.

The barn is cold and dark on this early October afternoon. Lyle—or “Spud”, as he’s known—flips a switch. Fluorescent panels flicker and light up a center aisle scattered with sawdust and two long rows of empty stalls, each wide enough for two cows. Across cracked windowpanes and red ceiling I-beams, dried specks of feces and hay cling to cobwebs resembling fraying scraps of pantyhose. On the right, seven calves lie in their pens. A flock of sparrows perches above them on round steel bars.

Spud, 68, ambles, too, walks with his toes turned the slightest bit inward. He’s tall with a greying moustache and always wears a fading green cap. He checks the stalls on both sides and picks up a long white stick—“not having a stick handling cows is like not having a wand when conducting an orchestra.” He swings the red barn door open. The cows file in. When they make it past the doorway, the cows bound down the center aisle of the barn, find a stall to their liking and hop in, heaving their bodies over the small ledge with their hind legs, and then sticking their heads into the feeding trough to get at tufts of hay left over from the morning. Spud is quick on his feet now, dancing around the cows to direct them into the right stalls. A cow comes trotting in through the door.

“I want you–” Spud points with his stick. The cow leaps into place.

“You go there.”

“I know you want to, but you can’t.”

“No, no, don’t go there.” The cow reroutes. “Thank you!”

Suddenly, the huddle of cows around Spud disappears. He cranes his head toward the entrance. A cow lingers in the doorway. “Come on in!” Spud says, as though welcoming an entourage of dinner guests.

Spud Edwards has been farming organically since 2002. He was one of the first to be certified in this valley, just as an organic milk market began to sprawl across the United States. Spud was new to Westfield then, having come only five years before by way of a long list of Vermont towns where he’s owned his own farm or worked for another. Organic milk was new here, too—at least the kind that is pumped into silver trucks and shipped to processing plants, where the milk is pasteurized and bottled for store shelves. Organic certification for dairy farms has been around since the late 1980s, but up until 2000, there had only been one certified organic dairy farmer here, and that farmer had carved out a regional market for himself by making his own yogurts and soft cheeses. The rest of them, those who sold their milk in bulk, had to wait for the organic milk truck to come to them.

In the mid-90s, concerns over the use of growth hormones led to ballooning demand for organic milk and new shipping routes for organic milk sprawled across the state.1 Farmers transitioned in waves. When the milk truck did come, almost everything would come to look as it had before: pasture and hay fields framed by blue-green mountains. In 2000, the average farm in Orleans County had 80 cows, and that was large for this narrow valley. Most farmers were already reliant on pasture—a central requirement for organic dairy—and in many ways were farming “organically” long before there was a need to label it as such. In barns and on fields, farmers carried on much as they had before. But a regulatory and economic calculus would come to settle over this valley—one dictated by the values we embed in our food, ideas of what is natural and what is good—making and re-making this valley in Vermont’s pastoral reputation.

____________

When I first wander into Spud’s farmhouse on a late July afternoon, he is in his office, reading an article about alleged animal cruelty at a 14,000-cow organic farm in Texas. It’s a great place to be a cow, the farm’s motto reads. The videos filmed by animal rights activists show cows standing hock-deep in manure, calves thrown around, animals dragged across concrete by their necks. The USDA would later publish a letter stating that the claims were unsubstantiated, but the damage was done.2 Kroger—the largest grocery chain in the U.S.—had already pulled the farm’s milk from its shelves, further cementing growing consumer concern that organic agriculture is no different from its conventional counterpart. 3

“It irritates me to see that mega-dairy model coming into organic,” Spud says, in that frustrated manner I would come to know well, a string of words tied together by a single breath. The office in his window frames two heifers grazing on a patch of pasture,

With his 50 organic cows pastured in the summer, Spud’s farm resembles in many ways the ideal American family farm echoed in mainstream conversations about food and who produces it. These conversations usually uphold the local, small farmer as a noble character, selflessly producing food for our families and distinct from what is understood to be perversely commercial industrial farms. Indeed, popular criticisms of industrial agriculture often wistfully call for a return to the small family farm, suspending a collective illusion that they are somehow pre-commercial—what agriculture would look like if only rogue capitalist forces had not perverted it.

But the ideal of the family farm is a moving target, evolving with dominant conditions of agricultural production. The family farm of 1950—say, a dozen cows milked into buckets—is more likely now labeled a hobby farm than anything else, not serious enough to feed the masses.

There are a few yellowing pages of an old farming magazine that Spud keeps in the bottom drawer of a filing cabinet. On the front page: a younger Spud grinning wide as he does now, hands in his pockets.

“This is me when I started in 1977,” Spud says, holding the pages out to me. Spud was 24 when he bought his first cows—23 of them, kept on a 25-acre parcel of rented land in East Peacham. But Spud had been around cows long before then, all the way back to when he ran around his grandfather’s farm as a toddler, a blonde head barely peeking over the barnyard fence—wooden, with steel hinges that his grandfather had smithed himself.

Spud’s grandfather, Harley Edwards, was a small and stern man, with few words to say but to bark at anybody that would trample down his hay on their way to the brook. His was one of those sidehill farms that sit strong in Vermont’s cultural landscape, with pasture creeping up a rocky knoll behind the barn, land that looked like only livestock could make good use of. People say this about Vermont land in general, that it is useful for growing hay and not much else. It’s said by way of explaining the state’s dependence on dairy, even as there is bottomland that is perfectly fine for growing food, and these forested hills had supported other kinds of agriculture for millennia prior. 4

The 16 cows that grazed on this hill were milked at five in the morning, a deathly quiet hour in the winters and sputtering with birdsong in the spring. Just shy of eight, Harley would be back in the farmhouse and sat at the dining table with his Bible open. Orphie, his wife, would be finishing up a full course breakfast. At noon, there’d be another full course meal, and then again at five in the evening for supper. The cows would be waiting to be milked afterwards. Harley would be done by eight at night, when he’d slip back into the kitchen with the yellow backsplash and the cabinets painted white, stirring flavorless cross crackers into a bowl of milk, the Bible open beside him.

“You could set your watch by him,” Spud says. On Sundays, they’d go to church and rest—Harley did, and Orphie, too, who’d spend all week cooking and tending to the children and grandchildren. “They relaxed, and napped, and shit like that.”

Days signposted at five, eight, twelve, five and eight again, more or less the same year-round. In the summers, the hours between milking would be spent out in the fields cutting hay for winter feed, or out at the quarry where Harley “worked out,” as Spud and other farmer-folk call working for anybody but yourself. Winter days were more up in the air—maybe some blacksmithing during the day, rigging up old car parts to make farm equipment. “You start the day with milking and end the day with milking,” Spud says. “In between, you don’t know.”

When Spud was old enough, he’d help carry the buckets from the barn to the milk house, where he’d stand on a chair and pour the milk into tall milk cans that’d weigh 100 pounds when they were full. Then they’d be placed in a box filled with water from the well to keep cool until a truck came rumbling down the road to take them to the processor. Other days, he’d tend to the calves, once taking one home to his family’s small house on a street corner to raise for a few months. Or he’d idle by the barnyard fence, peering at the bull in there with the cows.

There’s a wrinkled paper shopping bag that hangs on a wall in Spud’s farmhouse now, kept by his mother and framed by his wife. Scrawled all over it in ballpoint are things that resemble brooms with square heads: cows that Spud had drawn as a three- or four-year-old. At school, he’d fall asleep with his head on the desk and dream about cows out on pasture.

When Spud first talked of buying his own cows, his father would say, “Too much work and no money.

It wasn’t as though Spud's father’s career was particularly lucrative—he was a carpenter and worked at the quarry —but starting a small dairy farm was another story altogether. Spud’s farming career came at the end of Earl Butz’s time as Secretary of Agriculture under Nixon and Ford. Butz slashed federal price support programs for farmers, including a popular New Deal buffer stock scheme that allowed farmers to sell grain to the government in times of surplus and repurchase in years of low harvest. The buffer stock scheme—or the “ever-normal granary”—accounted for the inherent instability of agriculture, cycles of crop surplus and failure, by using those years of bounty as an automatic stabilization mechanism. In place of the ever-normal granary, Butz removed production limits and implemented direct payment subsidies that propped up farm income in periods of low prices, incentivizing farmers to produce as much as possible regardless of the market price.5

Butz’s mantra—“Get big or get out”—would soon materialize across the country, as farmers folded idle land back into production, and made use of new technologies that were emerging out of those same years to maximize grain yields. Farms with smaller land bases or less access to capital were suddenly unable to compete, bringing on a huge wave of farm consolidation that persists today. In part, Butz’s directive to “plant fencerow to fencerow” was responding to rising food prices brought about by a global grain shortage in the early ’70s. But the 1973 Farm Bill was also undergirded by a strong laissez-faire philosophy that argued food should be as regulated (or deregulated) as any other commodity, despite being a uniquely inelastic good: we can only eat so much. 6

Cheap grain in the 1970s spilled over to the dairy sector, itself undergoing pressures of growth and consolidation. When Harley Edwards stopped farming at 75, he was just about ready to retire. But Spud tells me it was more so the bulk tank that made his grandfather sell the last of his Jerseys. Beginning in the early 1950s, milk processors pushed farmers to install large silver tanks in their milk houses that would directly receive milk pumped from the barn. They’d come to replace milk cans and made milk cheaper to handle for processors. For farmers, who would end up bearing the costs of the machines, it didn’t make things much easier, except to save the effort of hauling milk cans and buckets back and forth. 7 Eventually the large cost and increasing mandate to install them forced many to stop farming altogether. By 1960, the state had lost half their farms. Farms grew; land in agriculture stayed relatively stable in that same decade. The cows begun eating grain. The milk was flowing, faster than ever, feeding a growing glut across the United States.

____________

As for Spud, evening milking begins at 6. He turns the radio on. The Beatles wail over the speakers, dusty voices filtering through static.

“Come on,” Spud calls. “Time to get to work!”

The cows heave forward on their front knees and then straighten their back legs. A few stay down, their limbs tucked underneath them in a bed of sawdust. They blink sleepily, opening and closing their mouths in slow circles. Spud digs the heel of his boot into their rumps.

“Let’s go,” he says. He walks to the end of the barn to switch on the gutter scraper, a long chain with metal bars that clean out a trough of manure behind the cows. It loops along one edge of the walkway and then back up the other before depositing waste into a concrete-lined pit behind the barn. Every few feet, manure has spilled out of the gutter in thick green-brown pools.

“Oh, Jesus,” Spud says, gruffly. “Look at that friggin’ mess.”

“Haven’t you been doing this for 40 years?” I say.

Spud laughs.

He pushes along a cart of sawdust with a flat tire he also curses on most days but hasn’t gotten around to fixing. He holds a bottle of beer in his left hand, pinching it against the side of the cart. He takes a swig. I grab a hoe and begin scraping manure off the walkway and from underneath the cows. When I’m done, I bring an empty cart to the sawdust pile out back and fill it up, plunging my shovel in the pile to break up wet clumps. I circle up to the hay loft and toss bales down through a hole in the ceiling. Back in the barn, there’s more shit to clean. Spud finishes spreading sawdust and goes to feed the cows.

Today, the cows are eating a batch of hay cut early in the summer, dark green and choppy, dead flowers curled up in the mess, petals pressed flat when the hay was rolled tight many months ago. In the first few weeks of June, farmers across Vermont pull themselves into their tractors and take the first cutting of their fields. The grass would have been growing all spring, the fields speckled with yellow dandelions. Behind them, they tow a hay combine, a long knife that runs over the fields until they become piled thick with soft plumes of cut grass. Leave the grass out to dry and the grass becomes hay. Most grass, though, becomes haylage. The grass is combed into long windrows and left to wilt for a few hours, the blades beginning to fall limp over another, before being rolled into large bales and then wrapped tight in netting and white plastic sheeting. They stay stacked at the edge of fields for months; from faraway, they look like marshmallows.

The grass begins to ferment. Chemical bonds realign, assembling broken down sugars into acids. In the winter, the hay is frozen when it comes into the barn and smells like nothing until the bale is unwrapped and the thawing ice loosens its hold. And then it unfurls in dense sheets—the hay, and its smell, like sour honey and plum wine. The cows push and pull at it, grabbing large clumps at a time. Inside their mouths, a hard rim of flesh at the top mashes against a short row of wide bottom teeth, breaking up the hay just enough for the cow to swallow.

When there is a lot of protein in the hay—always, on this farm—the cows make more milk. Their manure is also more liquid, something close to diarrhea, pouring out of their anuses in a steady deluge and splattering across the walkway. That’s normal, Spud tells me.

Spud feeds his cows corn, too, ground into a fine yellow and white dust. He makes the round of the barn, tossing a scoop of cornmeal at each cow. The powder clings to their eyelashes. The cows snatch up bits of hay where the corn has fallen.

Feeding corn to dairy cows is relatively new, beginning in earnest after World War II when grain prices began to fall. It’s a miracle for the dairy industry. Corn is high in starch. It’s quickly broken down in the first quarter of the cow’s stomach, the rumen, and provides a cheap and rapid source of energy. Corn-fed cows produce more milk. Spud doesn’t feed much corn, just enough to get his milk production up to profitable levels. He doesn’t grow any of it, either. Most organic farmers in Vermont don’t.

When cows eat grass, made mostly of cellulose, it is fermented in the rumen over the course of several days. The grass is swallowed, then regurgitated, chewed, and swallowed again, the saliva neutralizing the acidic products of fermentation each time. Corn, on the other hand, is fermented so quickly that little cud is chewed. On a corn-based diet, the rumen goes into acidic overdrive. Lactic acid shoots up the esophagus. A foam forms around the lining of the rumen. The stomach is bloated with gases that can’t escape.

The tendency to push cows at the expense of their health comes with thinning margins in the conventional dairy industry, which is challenged with falling prices and consequently, chronic overproduction. Meanwhile, the twenty-odd farmers in this valley are paid a steady premium for their milk. They’re members of the Organic Valley cooperative, founded in 1988 in Wisconsin. Organic Valley holds roughly a third of the market share in organic milk sales with just over 1000 members who collectively govern the cooperative through regional delegates.

Organic Valley is one of the few cooperatives in the U.S. that have a quota system to temper the inclination for agricultural commodity markets to overproduce. Farmers are only paid a set base price up to a certain level of production, after which the prices drop. In this way, prices have remained steady, more-or-less, with the exception of a downturn after the 2008 financial crisis and a recent period of organic oversupply in 2018. There’s less of a need to jeopardize herd health to keep the business afloat.

What grain Spud does feed, he buys from Morrison’s, a grain company based in Barnet, Vermont. It’s cheaper to keep fields in pasture or hay than to grow corn without synthetic inputs—as is stipulated by USDA organic regulations—especially when Spud doesn’t feed much of it to his cows. Besides, on an organic farm, 30% of a cow’s dry matter intake must come from pasture during grazing season—120 days of the year. A 50 cow-herd needs about 20 acres to graze in the spring, and closer to 40 in the summer and fall when the grass takes longer to come back. With his 97 acres, Spud does not have the land base to pasture his cows and to grow enough hay; he buys about half of his hay from elsewhere. And he certainly does not have the land base to grow corn on top of everything else.

Here, few farmers do. The fields stay green.

Over the hill, in the Irasburg-Coventry valley: a landscape perhaps more emblematic of the dairy industry these days. Corn fields from a single 2000-cow conventional farm amidst a smaller, scattering of organic farms.

“I gotta go to the store, get a coffee,” Spud says one day after milking. The sun is just up. The hill behind the barn, trees bare of branches, is the color of a plum split open. “Wanna go? It’s a ritual I do every morning.” Spud pulls out onto Route 100. We pass by barn after barn. That farm sold out, Spud says, nodding at a light turquoise barn with a big wreath hanging above the main door. That one’s “in debt up to their ass.” I glance out the window and see green after green, no signs of failure, as though the landscape had sewn up its wounds.

The past few decades have been marked by declining milk prices across the United States.

Here are the milk prices that Vermont farmers received from 1980-2019, adjusted to today's dollars.

As elsewhere, Vermont farms—smaller ones in particular—have closed. Between 1980 and 2017, the state lost 80% of its dairy farms.

Meanwhile, milk production continues to increase as remaining farmers expand their herds in pursuit of higher margins.

But still, Spud says, "Organic saved this county."

Organic Valley prices have remained more or less above cost of production, offering an cushion from the volatility of the conventional sector.

Indeed, the number of new certified organic farms seemed to increase in years following price troughs, or after events that sparked demand for organic milk.

Vermont farmers, along with farmers from other high producing regions, stand to gain the most from this price premium, creating a distinct spatial distribution of organic dairy farms.

Unlike organic milk prices, conventional prices are federally regulated, and where you are determines how much you get paid for your milk.

It’s all a bit of a black box, a tangle of convoluted formulas that nobody—including farmers—really understand, but the regionality of milk pricing comes through loud and clear. The milk market is carved up into regional pools—Federal Milk Marketing Orders (FMMO)—in order to temper competition within pockets of demand and ensure stable and minimum prices for farmers. Vermont is part of a pool with most of the New England states and a few others along the East coast. Pool members all share what’s called a blend price, determined by how much of each dairy product is made in that pool.

Say, one farmer sells their milk to a cheese plant that pays a federally determined price of $16 dollars per hundred pounds. Another sells to a fluid milk plant that pays $18. Both producers get $17 dollars—the blend price—out of the pool.

Now add the Class I differential to the equation. For raw milk intended for fluid milk (and not butter, chese, etc.), processors pay an additional cost depending on the location of that plant. When Federal Milk Marketing Orders began at the height of the Great Depression, that differential was calculated based on the plant’s distance from Eau Claire, Wisconsin. At the time, Eau Claire was considered the highest producer in surplus milk. The further you farmed from Eau Claire, the more you were rewarded, in a sense, for your product.

It was assumed that if producers were not making milk close to the plant, then the processor would have to pay for the transportation to ship that milk in from a higher-producing region. That system was more or less phased out in the ‘60s, but what replaced it was in effect the same, except that it more actively accounted for regional demand.

In a low-production high-demand region like Florida, farmers are paid the most. As you move north to New England—high-production, high-demand—the differential shrinks. It gets worse out West: few population centers and way, way too much milk.

Class I Differential ($ / hundred pounds)

On top of that, Vermont dairy farmers have some of the lowest margins.

production margins per hundred pounds

(not incl. overhead)

And perhaps as a result, also one of the highest percentages in organic milk sales.

organic sales (%)

In 1997, Organic Valley representatives came to Westfield looking for new members. They met, almost 50 farmers all told, packed in a little white community building tucked away by the town offices. Grain dealers were there; so were seasoned organic farmers who assured the crowd that it would be a smooth transition. A higher pay price was promised. Two years later in October 1999, Organic Valley would start its first Vermont milk route. Six months before, Horizon Organic, today a corporate agribusiness conglomerate, purchased the first bulk organic processor in the Northeast, the Organic Cow of Vermont. Horizon was expected to drop the pay price from $21 per hundredweight to $18. Many of Organic Valley's earliest members in Vermont joined the cooperative following this acquisition. 8

If it wasn't for the premium, Spud wouldn't be farming organically. He'd likely not be farming at all. Organic dairy farms can stay small, propped up by the higher prices consumers are willing to pay for a product that seems better—for you and for the environment—and by the supply management systems that keep farmers from pursuing even greater margins. It's a paradox that forces a reckoning between the economics of commodity agriculture and the philosophical origins of organic.

The rise of organic agriculture in the past few decades—or at least its rise as a collective, so-called alternative practice—is most often referred to as a movement, a revolution, even. And yet, a true revolution, a complete turning of the land toward methods of organic production, would flood the market and annihilate prices for farmers. In the past two years, those who've wanted to join the movement—those who've phased their land out of corn and back into grass, turned their cows out on pasture for their first time—have been held off from joining Organic Valley. There's too much milk in the market.

Meanwhile, the farmers in the Missisquoi River valley are protected by the gatekeeping of organic. The prices came first, the philosophy after. "We're making a pretty good product here," Spud likes to say.

____________

“These fuckers are down,” Spud says, looking at a sheet with data on his cows: when they had their last calf, how many days they have been on the milk line and when they are due next. Almost all of them are pregnant. One column reads their milk production in pounds, which is lower than usual for this time of year.

“I don’t like to call them that, but I do when they’re down,” Spud says.

“I thought you loved your cows,” I say, laughing.

“I do. I do.”

“You just called them fuckers.”

“I know,” Spud says, ashamed. “I apologized. I took it back.”

Spud reads these tables on the toilet. The crinkled sheets of black digits and letters sit wedged in a pile of cooperative newsletters and bull semen catalogues under the bathroom window. Date of calving, number of days in lactation, pregnant? (Almost all of them are.) The bull semen catalogues are another collection of data tables, only these are printed on glossy pages beside panoramic landscapes of high contrast green fields and a sky the color of a summer peach. The sky fades to a deep maroon at the page’s edge; the cow, with its creamy white coat stands supreme at the center of the page, encircled by a halo of darkness. Its head is held high by a pair of invisible hands, Photoshopped out. Its udder is bright pink, swollen and crawling with thick veins.

The bulls, each sporting a name more ridiculous than the last—Rager Red, Hired Gun, Hotstuffs Hypnotic—are scored on physical characteristics like strength, stature, and rump angle, although none of these values refer to the bull itself, but rather to the daughters the bull has sired. Every few months, somebody from the Holstein Association strolls the length of Spud’s barn, dipping their head to take in the cows’ udders, teats, feet, legs, and notes down the number on their yellow ear tags. Spud’s cows, like most Holsteins, are registered in a large database managed by the HA that tracks cow’s physical form along with their dams and sires, thousands of data points spanning the globe that are eventually aggregated into averages for bulls featured in semen catalogues.

At cattle auctions, the lineage of cows is thoroughly documented in the sale book to assure buyers of their genetic purity and their production value. I join Spud one October morning at one of these auctions at a farm in central Vermont.

The gravel lot is already full with pickups when I arrive fifteen minutes early, caked in dirt from the dusty drive on this dry autumn day. I find Spud by the heifer barn. We take a tour of the cows.

“That’s a massive udder,” I say, eyeing a cow in the barn. The two back quarters are bulging on either side of a deep cleft.

“Oh yeah, they’re backed up,” Spud says. He looks about the barn. “They’re nice.”

The milk is leaking out of distended teats, spraying out of some, a slow drip out of others. The cows weren’t milked this morning. Otherwise, their udders would be half as big, only part way through the slow refill that ends at evening milking. Spud’s not here to buy; the cows on this farm are not organic. But each cow here traces back to a dam one or two generations back, themselves bred to some elite bull farmed elsewhere for its semen. A dairy bull’s lineage is closely tracked according to the qualities of its female offspring and their offspring, and so on—udder shape, feet and legs, production volume. When the auction begins, Spud will look the cow up and down, lean toward me, and over all the hollering, say, “She doesn’t have a good udder” or “See, that’s a good cow there.” And then he’ll note down how much the cow had sold for, thinking, maybe he’ll buy that cow’s grandsire’s semen for his own herd. There’s no such thing as organic semen, only cows—female, lactating cattle—who graze on pasture, and eat corn grown without synthetic inputs.

Many of the cows on this farm, rarely enough, were bred with bulls raised here. We find two of them pacing in the shadows of an open-walled barn. Leo and Lou. It occurs to me that I’ve never seen a bull before. It wasn’t particularly likely that I would have, having grown up in cities and all, but the bulls’ bodies felt alien to me in a way that cows did not when I saw them up close for the first time just several months before. The few bulls I’ve seen on television have never been dairy bulls. They were brown and squat, with violent horns and muscles that bulged under their skin. These bulls are tall and lean. Both of them tower above me by almost a foot. When they turn to make another round of the pen, I think, their legs are so long, partially because they end almost at my shoulders, but also because I’m so used to seeing a large udder swinging between the legs of dairy cattle that I forget for a moment that male cattle don’t have udders.

“I don’t like bulls,” Spud says. “’Cause they get ugly. You can’t trust the bastards. They’re mean. They’ll kill you if you let ’em, if you turn your back on ’em. You never know when they’ll turn, that’s the thing. Look how big they are, their friggin’ heads weigh more than you do.”

“Probably,” I say.

Spud pauses.

“Nice looking bulls. They definitely got the bull look to ’em.”

The bulls stick their heads between the metal bars and into glaring sunlight, one to plunge its nose into a pile of dry hay, the other to get a closer look at us. A large brass ring has been pierced through its nose. A chain, more than a foot long, hangs from the ring, its links tinged with rust and shit. It clangs against the metal pen. Above its bulbous eyes, the skin has gathered in tight wrinkles, deep parentheses that stop at the white curls on its forehead. The head is faceted with muscle. A hump rises above the neck.

A man in worn plaid walks by, and says, “That one’s mine:

“You trust bulls?” Spud says.

“Yuh,” he said.

“You gonna buy one?”

“I might.”

“They’re big though.”

“Yuh. I don’t want one that big.”

“No,” Spud says. “They’re hard on cows.” And then to me: “You know, when they’re on top of ’em.” He chuckles.

The man who used to run this farm is said to have been one of the best cattle dealers in New England. He died a few years ago while moving cattle from one farm to another—heart attack; he was 73. It is said that Sonny Miller would milk his cows in the mornings and evenings, just like all the dairy farmers that once lined this dusty road, only he’d be holding a phone to one ear, and have another sandwiched to his shoulder as he’d make deals with farmers and cattle breeders, the twisted cables swooping across the barn and in between his cows. There’d be two other phones on the wall trembling in a flood of calls. Now, his son is selling the farm.

“Cows look good,” Spud says when we run into Shaun Miller by the auction tent. “Holy smokes, they got some milk in ’em.”

“Yeah,” Shaun says, almost wearily. He looks past us, as if eyeing the bare corn fields across the road.

“Some nice udders.”

“Yeah, they’re a nice set of cows,” he says, quiet.

“Hopefully they go well,” Spud says.

“Why are you selling?” I ask.

“I don’t want to milk cows in the winter.”

“What are you gonna do this winter, Shaun?”

“Not milk cows.”

“You going to Florida?”

“I’m gonna not milk cows.”

“’Cause you haven’t missed any milkings, have you?”

“No,” Shaun says, his voice high with indignation for a moment. “I’ve fed my calves every feeding this year.”

“Yeah see he never gets away, that’s why—now he’s burned out.”

“No, I’m not burned out,” Shaun says.

“No? Just wanna take a break.”

“Well, no, you know I’m just breaking even. But I could do a lotta things and just break even.”

“Without working?”

“I could do nothing and break even.”

Spud laughs. He asks about the corn across the road, who those fields belong to. Shaun mutters a name, and then as Spud begins telling me about corn fields turned more profitable hemp fields, Shaun scans the horizon again before slipping away and disappearing into the auction tent.

There are already people seated around the auction pen, an octagonal cage painted green with dried corn and hay bales marking every vertex as decoration. Through the tent roof, the sun throws a yellow tint on everything. By the time we find our seats, a row of people has gathered at the edge, their backs stuck in sunshine, their faces cast in the shadows of their caps.

“Check, one, two.” A deep voice churns out of the speakers. “Well folks, I’d like to welcome you here to the Ryder-Brook Farm Complete Holstein Dispersal. We have about 315 head to sell to you today so we have to do them rather rapidly.” Dave Rama, the auctioneer, sits at a podium looking over the pen, and speaks with his lips almost brushing the microphone. He scans the crowd; his eyes are slits. Black sports sunglasses are perched on his large head that seems to sink into his shirt collar.

“I know that the Millers certainly need no introduction. They’ve been a big part of Vermont, Holsteins, and the cattle world and agriculture for years. Shaun is back here. His lovely wife is right back here as well, and I’ll tell you. Shaun has done just a remarkable job, a remarkable cow man, has a tremendous group of people working here on this farm.”

Dave continues for a while, pouring praise into the microphone. “Folks, I’ll tell ya,” he finishes. “It is one of the sweetest-uddered herds that we’ve had the privilege to sell.”

The bulls are for sale, too, Dave says, only he’ll sell them out in the back pen.

“Actually, we just got an announcement,” the man—Tim Abbott—sitting next to him says. “Dave Rama is gonna lead that big bull in the ring. If anybody wants to see that. That’ll be a lot of fun. Actually, your wife would like to see that. She wishes it had horns though.” He chortles. The audience titters.

“Right, right,” Dave says. And then he continues.

“And I gotta tell ya some’n. If you’re in the heifer business,” he says, pronouncing heifer like halfer, “Shaun—I’ll tell ya—he went to Langmaid’s.,”—a renowned breeding farm in central Vermont—“He went down, he said, “I like tremendous udders. I don’t push my cows hard. I like tremendous udders and feet and legs”, so he went down and bought some bulls from Langmaid’s out of 94, 95 point cows”—udder looks are scored out of 100—“with 50,000 pounds of milk and he used them in his herd. You know, I gotta respect somebody that does that because I’m gonna tell you some’n. I told Tim Abbott, before he got here at crack, I said the best set of heifers maybe I’ve ever sold at a sale I’m going to sell at this sale. They are amazing. Best set of heifers from top to bottom. Don’t have any pink eye in ‘em. They’re all right. No hernias. They’re clean. They’re big for their ages, and just a sweet group of cow. So without further ado, I think we’re ready to get started. Folks, we are handling a few bids.” He introduces the man sat at the front of the audience, who’s receiving online bids on his laptop. “That’s Chad Griffith. Very handsome young man from Ohio. He’s a big Bernie supporter. We’re glad to have him here.”

“He’s probably the only one here,” Tim says, cackling. Dave laughs, too, and then puts in his last glowing pitch for the cows before ordering the first be let in. A gate on the left side of the pen slides open, and a cow bounds into the pen, legs flailing. It circles around and back. The two men in the pen, one with a wooden shepherd’s cane, redirects it to give the audience a full look of the body, the udder, the feet and legs. Spud points the cow out in the catalogue—lot number 85. The page is packed with numbers, plus signs, and decimal points, names of dams and sires in bold: data of the cow’s milk fat content, bacteria count, volume, the cow’s pedigree. Lot 85 is the daughter of Mr. OCD Epic Dragonheart and Walhowdown Secure Raspy. On other pages, dams are pictured against a Photoshopped green field and a trim of forest. The cow stands stiff and regal, one of its back legs stepped forward to display the udder. The coat is clean: a sheen on the black, and a raw white with the lightest of pink where the hair has been shaved close to the skin. On one page, there’s a close-up of a bright pink udder, cropped and captioned in a cartoonish font: “Treasure’s beautiful mammary!”

“Oh, so that’s a pregnant one,” Spud says of lot 85, scanning the page.

“Lot number 85, and let’s roll, David,” Tim says. And then out of the speakers comes a rumbling of numbers. Dave’s tongue is rattling in his mouth. His lips barely move.

“Do I have a five hundred five hundred five hundred I got a thousand now a twelve hundred twelve hundred and a twelve and a twelve now a thirteen a thirteen a thirteen a thirteen hundred now a fourteen fourteen can I get a fourteen hundred now a thirteen and a half.” Dave takes a sip of a breath. Every few notes, his song pitches upward before lowering again into a flat litany. He’s speaking cursive.

“Thirteen and a half fourteen can I get a fourteen—what a heifer!—can I get a fourteen can I get a fourteen…”

One of the men in the pen stands poised with his right hand stretched out to catch new bids. With a flash of a bid number, the man calls, almost screams.

“Yeaap!” A blaring note, vibrating as though catching a strand of phlegm at the back of his throat.

“CanIgetafourteencanIgetafourteen…”

“Yeaap!”

“Fourteenandahalffourteenandahalf…”

“Yeaap!”

“FifteencanIgetafifteenfifteenfifteencanIgetafifteenhundredfourteencanIgetafifteen…that’s a buy for fourteen and a half!” The half skids on and bends into a higher pitch.

The cow slips out the end gate. And then it’s on to the next.

“Another very good cow,” Tim announces. “She’s already very good. She gave 24,000 pounds out of that beautiful udder, fresh the 8th day of September and ready to roll. Look at the udder on this cow”— “Whew!” Dave says— “milking extremely well. She made 24,000 pounds of milk last time, David, and bred right back. Beeaauutiful cow, and just fresh.”

“CanIgetathousandnowtwelvehundredtwelvehundredtwelveandahalfnowthirteenandthirteennowthirteenandahalf…” There’s already a lull in this sale. Dave is stuck on a price that is far too low.

“Thirteenfiftythirteenhundredandtwentyfivetwentyfivetwentyfivenowaquarterthirteenhundred twenty five–“ Dave breaks off. “That cow is just fresh!”

Tim jumps in, “Fresh fresh the first part of September, cow calved as a two year old and a three year old.”

Dave makes a sound somewhere between a moan and a squeal.

“This cow’s gonna be a hundred-pound cow if you get her home.”

The morning slides into the afternoon. The crowd is shifting in their wooden seats, leaning forward to get their bids in.

“This cow will fill your sink and tank right here. I mean that’s a milk wagon.”

“I’m asking thirteen hundred and this cow—look at the cleft on that udder, I mean, just beautiful.”

“She had 71 pounds out of that beautiful udder. Pregnant pregnant pregnant!”

“88 point cow. She was fresh the 18th day of September and ready to roll. Let’s sell her before she gets everyone dirty.”

“That $100,000 cow, that ATM cow and a pretty big pedigree by the hottest bull in captivity.”

“Wowwowwow.”

“87 with an excellent mammary—you can see why. This cow’s giving a looaaad of milk.”

“Look at the ring boys.”

“Ohhh, my dear. Fresh and fancy. Ohhh, rolling out the milk again. Here we go.”

I’ve pushed the sleeves up on my blue sweater, its cuffs soggy and rimmed in brown. Forearms: crusted with layers of iodine solution and milk and cow shit, a rusty orange stippled with a muddy green. Splotchy, as though someone had dribbled liquid onto a watercolor painting. I fumble blindly for a cow’s teats. This one’s young, with a small udder, four quarters hanging like pink tents turned upside down, so I have to reach up behind the stainless-steel divider that separates us to clean her teats. I stick my head under the divider to check that I’ve got all the dirt off, hoping that the cow does not decide at that moment to let out a fresh turd. It happens, I am told.

I spent the five weeks of my winter break milking cows at a 500-cow dairy. I wanted to know what organic was made in response to, the industrial ways of food production with which most are unfamiliar. And yet with each meal, we interface invisibly with these food systems, altogether a bodily encounter with the strange. The farm I’m working at is in Canada. It’s where I could find legal work as a Canadian citizen. But the methods of dairying are, with the exception of some deviations, a mirroring of industrial dairy production in the United States.

The milking parlor is a rectangular pit a few strides wide and about the length of two small cars. Milking claws, four rubber-lined metal cylinders attached to a central plastic body via black hoses, hang limply on chains in two long rows either side of me like huge sedated bugs. There’s 32 of them, one for each cow that files onto the concrete platforms on each side, their bristly hocks at eye level, their hooves smacking on a chunky sheen of manure and urine. The first walks the length of the platform, reaches the end of the narrow corridor, and rotates 90 degrees. As she turns, a gate folds in after her and locks her into place. Her head is sandwiched between steel columns. The next cow does the same. Clops along, rotates. And the next, like soldiers falling into line. Soon, the view from the pit is two rows of udders and the white backs of their legs. The rest of their bodies are blocked off by a stainless-steel panel running the length of the parlor, with consoles controlling each milking unit, a few brightly colored buttons and an LCD panel. Four red digits blink, then settle: the cow’s ID number, picked up off an RFID tag wrapped around their front left ankle.

The cows—480 of them—are milked three times a day in five-hour shifts. The first begins at four in the morning. From the highway, the farm is a grid of cold-white squares hovering over a hill shrouded in darkness: the plastic siding of a long and squat barn lit from within. I find the milking parlor at the end of a gravel lane. In the greenish-grey of a fluorescently lit room where everywhere else is dark, the milkers are already running in a chorus of mechanic inhalations and exhaliations, drawing milk through an elaborate system of pipes and into the bulk tank in the next room, a steel cylinder the size of a small school bus.

I am put right to work. Ben Loewith is short and lean, 44, and the third generation to be running the farm. He talks fast and doesn’t so much as walk but charge, his body at a permanently slight angle with the ground. He hurls procedures and protocols at me. We prep and milk four cows at a time in the row of 16, he tells me. He starts by “stripping” the first cow, squeezing the four teats to let out three spurts of milk each. The milk pools between the cow’s feet, swirling around flakes of dried manure, a brown and white slurry, like cookie crumbs soaking at the bottom of a milk glass. Stripping stimulates the udder, tells her body to let down her milk. Every now and again, a cow is infected with mastitis and her milk has coagulated into fine cheesy chunks. Stripping gives the first diagnosis.

Ben dips the cow’s teats in a iodine. He strips and dips the next three. And then it’s back to the first with a blue towel. The udder stretches and jiggles as he wipes the iodine and dirt off. Four cows clean. A green button on the console drops the milking claw on its chain and Ben swings it under the cow, bring the opening of each cup to the teats. The cups gasp before latching on with a thump. Milk gushes into the central body. The rubber hoses quiver.

Within five minutes of stepping through the glass double-doors, I am milking cows on my own. The cows kick as I grab their teats, gritty and pale with sand from the barn, or shift between each hind leg like a child needing to pee. They feel clumsy in my hands, these floppy tubes, and half the time, I squeeze, and the milk doesn’t come. I try different ways of holding the teat. Conventional wisdom has it like this: take the base of the teat—where it meets the udder—in the fleshy crook between your thumb and index, pinch, and then roll the rest of your fingers successively toward the palm. It doesn’t really work. I look down the parlor. The man milking the other half of the room has all his cows clean, his milkers attached. I’m only done cleaning my second.

But milking cows at this scale is work that gets better. By the 50 th, I am stripping with my left hand and dipping with my right. A second to each teat. I yank at them with the blue rag once, and then a second time to rub the tip with my thumb. I think of how my mother used to dry my hands after I had washed them, a five or six-year old with my hands held out splayed to her, fingers stinging from the friction of her grip. When I’m done with the rag, the teats are a baby pink, the color of a cartoon pig, and so bloated with milk that they’re almost shiny. Even so, grains of sand still cling inside the small crater of the teat opening. I leave them like that; there are more cows to clean. Besides the vacuum will whip the sand through a gurgling pipe of milk and then a dense fabric filter with catch it alongside microscopic specks of shit and cow hair. When the sensor picks up a slowing milk flow, the claw automatically drops off, jolting back on its chain like a playground swing after a child has ejected themselves. The teats will be spotless then; the tips are an almost translucent white, like the unraveling ends of a boiled sausage.

My boots slip on the slick rubber mats. I slide between the cows, shaving a few seconds off this new dance I’ve learned. Strip, dip, then wipe. Attach claw. I glance over my shoulder to check on the other row of cows. I can tell from a loud hissing that a cow has kicked off her milker. It lies on its side, tubes twisted, in a steaming pile of fresh manure. I hose off the milker, check the cups for clumps of shit, and then reattach her, milk spraying on my wrists. I slide back to the other side. Strip, dip, strip, dip. I’m moving as fast as I can, trying not to catch any snags in my routine. But then there are the cows with the rear teats so close together that they crisscross, and the milking claw—designed for four evenly spaced teats—sits awkwardly, squawking and squealing as the cups slowly slip off. Or the cows that stand too narrow, and I have to wrestle the machine between their bony knees. By the time I’ve managed to attach all four teats, I’ve leaked a bunch of air into the system, the vacuum loses pressure and the cups fall. I lose my patience a few times, curse and stand with my hands on my hips, sigh and then try again. Over time, things get even easier, and annoyances lose their sharp edge. It’s just part of the job. By my third shift, I feel like I’ve fallen into stride with this cadenced beast, like I’m an appendage on a machine that makes sure it runs.

____________

The cows get used to anything, too. Every few days, a cow comes into the parlor and doesn’t know how to turn. She files into the narrow corridor after the others, but as the gate folds in after the cow before her, she stops short. Her head is bowed, her nose inches from the floor. She glances around. She swings her head toward me, black with a white triangle on her forehead, and then away again. She paces on the spot. I tap the back of her leg.

“Come on, bub,” I say. She doesn’t move.

I grab the pink plastic cane hanging at the end of the parlor and poke her face. The round end of the cane bunches the skin over the flat bone of her muzzle. She blinks, pin-straight black eyelashes flickering, then she bows her head even lower and turns into the stall.

Slippery, mauve strands of translucent membrane hang out of her vagina, at the bottom of which swings a kidney-shaped pocket of pink fluid the size of my palm—the remains of a calf’s placenta born a few hours before. She’s “fresh”, in industry language. The calf was her first; this was her first time in the parlor, in this alien cacophony of staccato breaths. She’s not my cow to milk. Her stall is on the other half of the parlor, where Cookie is working. Cookie is a tall, stocky man of about 50, has kids that are my age. He hates the swinging placentas. He jabs his finger toward her.

“Your cow,” he says. “Your favorite.” He’s smiling, but I know he’s serious about passing her off to me.

“No, your cow,” I say. I smile back, and then go back to wiping the sand off my own set of cow teats.

Cookie doesn’t speak much English. He’s from Pakistan originally, and worked on dairy farms in Italy for more than a decade before coming to Canada. We speak in monosyllables. A few minutes pass. The clockwork rhythm of the milkers crescendo. Then Cookie tries again.

“Your cow,” he says.

“No!” I say, laughing.

Cookie furrows his brows.

“You go front.”

“Wait, why?” I ask. I had seen new, fresh cows come into the parlor before, but hadn’t seen anybody go and stand in front of them.

“She. Heifer.” Cookie says. “She kick!”

“Okay, but what do you want me to do?”

Cookie barks something short and waves me off. I roll my eyes and clamber up onto the platform where the cows stand. I find the cow in the long row swinging her head low left and right. Thin white steam tumbles from her nostrils, curls back off the concrete floor and around my boots. I hear the hiss and clang of the claw dropping on its chain and into Cookie’s hand, and then another hiss and thump as the first cup latches on. She jerks forward, her broad shoulders jamming up against the metal braces around her neck. I kneel down and hold her collar, because that seems like something to do, then the base of the ears, a small nob of muscle where cows like to be scratched. Hiiiissssss-thump. Hiisss-thump. She heaves forward again. Her udder swings. I hear Cookie curse as the milker falls off. I rub her forehead, a grey-white patch of short half-ringlets.

“It’s okay,” I whisper. “It’s okay.” I feel a little foolish reassuring an animal that will in a few hours be in the same spot, still trying to kick off this thing clinging onto her udder.

She stops swinging her head after a while, just keeps it low. The floppy skin on her belly quivers. The cow to her right rests her pink muzzle on the spine of her neck. In a few days, she will be broken in, the gasping machines no longer a shock to her. Today, the mechanic calf suckles, pulling a thick yellow milk from her udder and into a plastic white pail. This is the first milk—colostrum, a milk rich in antibodies, natural disease prevention for the newborn calves waiting in their plastic and plywood hutches outside to be fed from a plastic bottle with a red rubber teat.

____________

At 8:10, the morning sun has thrown a parallelogram of light through the front doors and onto a cow’s udder. I dip her teats in the post-milking iodine solution, more concentrated than the pre-dip. Earlier, it had reminded me of molasses. In the light, it’s a deep, pretty, red. I glance at the holding pen. It’s empty. Finally done, I think. I take my time dipping the next few cows. Then, I hear the quiet patter of hooves on concrete. I look back to the pen and see a wall of cows coming for the parlor, their black and white backs like waves on a restless ocean. Their heads sway. Some chew their cud, their mouths a frothy mess. They’re cute. But there are at least 90, maybe a hundred of them. I dip my cows faster now. I’d like to be done before 9.

____________

Every day, I plan to stay and watch the cows and the people, and then 9 hits and I’m ready for the long mindless drive back to suburbia, where I’m staying for these few weeks, my torso hunched over the wheel, my spine a limp noodle. By the third week I’m there, my body is less worn. I grab a cookie from the lunchroom, and wander around the barns, stopping to chat to the cows. The barns are long and cavernous things—free-stall barns—open on both ends and divided into four sections where the cows wander as they wish. Most of them rest in stalls bedded with sand. A few stand in the concrete walkway. There’s one stall for every cow—normal for Canada, rare for the U.S. where industry experts encourage over-crowding while still optimizing for production. Comfortable, but not too comfortable. Black clouds of swallows swirl and pitch under the vaulted ceiling. It’s nice in here.

At the end of one barn, I find a man with a thing that looks like a phone booth from another world. Red, rusty, all jigged up with pulleys and pneumatics and lightbulbs. It's familiar, in a way. The red reminds me of Chinese wedding litters, a square frame with an opening in the front and back, the steel and lightbulbs—incandescent and burnt-orange light—of Hong Kong street stalls in which old men in baggy white undershirts tinker with broken watches. It’s a hoof trimming jig. A cow files in on one end and a door on the other opens and clicks around their necks. Randy, the hoof trimmer, is wearing a padded jumpsuit and has the hood of his sweater pulled up and cinched around his face. It’s cold out, and besides, he doesn’t want the chips going down his shirt. Randy flips a few switches and the back of the machine rises up, pneumatic columns hissing, and a band comes up under the belly of the cow and lifts her onto her toes. A robotic arm—mechanic, not digital—grabs onto one of the cow’s back legs and brings it off the ground. Suddenly, the cow is doing yoga, leg stretched out straight behind her. Randy takes a circular grinder and goes at it, and the bottom of her feet, usually caked in shit, returns to a creamy white. Hoof chips go flying. I pick up one of the shavings and it reminds me of parmesan cheese flakes, only when I go to rip it, it doesn’t crumble. It rips like plastic.

“I’m returning the hoof to its natural state,” he says. He’s ground out a hollow in the center of the foot, two half-circles on each claw. Cows feet are harder around the edges; that’s where the pressure should be. Out on pasture, the dirt grinds away at their hooves. Here, where cows walk on concrete and have never seen a live blade of grass, the hoof trimmer comes a few times a year to fix their feet. Some cows limp, their toes overgrown or their soles worn through to the flesh. On these cows, Randy glues a block of wood to a harder part of their foot. The cow will walk on it as keratin builds up over her hoof again.

Carl—72, Ben’s father, a short quiet-mannered man—comes by to feed a calf that was born an hour earlier. The calf is almost all white; her fur is a mat of hardened curls. He has a bottle of murky teal liquid to disinfect the umbilical cord, and another bottle to feed the calf with. He also carries what looks like an IV fluid bag with a long plastic blue pipe. That goes down the calf’s throat if she doesn’t want to drink. But she does, and Carl holds the bottle until it’s almost empty and white saliva is strung between his fingers.

The calves rarely drink directly from the mother. “We’ve pretty much disrupted the mothering instinct in cows,” Carl says. The calves never get enough if they drink from the mother, he says. The cows don’t teach their babies how to drink. Beef calves, he tells me, always get enough—we don’t milk beef cows and besides, if they don’t drink, they die. On dairy farms, the farmers bottle feed them colostrum-rich milk from another fresh cow. Or they mix in colostrum powder with regular milk.

“We’re perpetuating the problem,” Carl says. He sounds a little forlorn, but I’m so surprised by what he’s telling me that I don’t think to ask how he’s feeling.

The mother cow, who’s been lying idly by, stands up, and one of her hooves catches the calf’s back leg.

“Hey,” Carl says, sharply. He taps the cow’s leg. “Don’t step on her.”

One morning in early July, one of those days when the sky hangs low and tamps down a still heat onto dust, I set up Interstate 91 to see a dairy farmer who is said to be a pioneer of alternative agriculture. I wanted to learn about the history of organic dairy, and I was told that it began on Jack Lazor’s farm, Butterworks Farm, more than 40 years ago. I was compelled by his story, too, by the strong philosophical commitment to agriculture that is good for the earth. Organic, not just for the premium, but as an intentional reflection on how the food we grow relates to other living things. I looked up to it as something I might want for myself someday. Jack had grown up in suburban Connecticut, gone to Tufts and decided that he wanted to “return to the land,” as it were. At the height of his business, Jack’s yogurt sold at Whole Foods stores in New York City and Boston, shipped down from his tiny farm in Westfield, a little town unknown to most. And all the while, young people have come from afar to learn how he built something from seemingly very little, who’ve gone to start their own farms. I was drawn to the romance of it all: the triumph of the small farm, hard work, simple living, tucked away in the Green Mountains.

I-91 skirts along the western slopes of the Connecticut River valley. It is hay fields to my left and to my right, and clusters of buildings at every exit, first larger complexes closer to home, and then as I move north, a scattering of brick and white vinyl. A lone gas station here and there. I pass through Barnet. The Passumpsic River comes in under me, signaling entry into The Kingdom. It’s hard to say what came first, the quiet and rugged myth of this corner of the state or the name—the Northeast Kingdom—that decidedly ensured its existence. In any case, after George Aiken in 1949, then senator of the state, blurted it out in a development meeting for the three counties flagging in poverty, the name stuck. There is, of course, no king in neither Essex, Caledonia nor Orleans County, but there is something about this place—something about the empty roads and thick forests and small, weathered buildings. After St. Johnsbury leaves my rearview mirror, I could swear there are more rubber-lined cracks in the asphalt, that there are more crows here picking at the black-pink flesh of tire-streaked opossums.

I peel off the interstate in the town of Orleans, and then turn left for Irasburg. Here, the road skirts by a hulking wall of dark silver granite. A gateway of sorts; a steep hill beyond. I begin to climb and then descend into the Missisquoi Valley, crossing state highways and narrow bridges with vegetation curling along its edges, trundle along backroads that turn from asphalt to dust. I stop for a turkey, who dashes in front of my car, hesitates and then disappears into the forest, brown feathers rustling a bed of ferns. And then a wooden tower emerges over the crest of the dirt road. A looming grey rectangle with a triangular roof and a severe spire. A steeple, dark against the blisteringly white summer sky. This, I would later learn, is Jack Lazor’s granary, which stands empty today on his farm where the cows have fed on not a single morsel of grain for the past few years, but only on grass and hay and molasses. Grass-fed: the latest in Jack’s prophecy of what will save the earth.

Jack’s house sits below the rest of the farm, cradled where a gentle slope blends into flat pasture. I find what I think to be the front door—although it’s hard to tell with all the tools stacked up around it—and peer in through the windows. A small figure, swallowed by a brown recliner, a faded red blanket piled on his lap. Chin to chest, he peers along his nose and waves me in.

He wears an old plaid shirt with the right sleeve cut off. Bright red plastic tubes sprout from Jack’s right upper arm and the crook of his elbow. The tubes swoop down and loop up to the dialysis machine in the corner. It hums a high tune against a hushed beat. At 68, Jack’s hair and beard are leached of color, and it looks as though he’s been standing out in a windy field with how his hair is swept to one side. Years before, that would have been true, but the only place he’s been since the first hours of the morning is in this chair, waiting, as the machine pulls the blood from his body, through the dialyzer and pushes it back into his veins.

“We were one of the first,” Jack says, as soon as I settle in. He speaks softly, his words deep and rounded off with a musical lilt.

Jack and his wife, Anne, found their first footing in Irasburg, Vermont, a small town down the hill and over another from Butterworks. This land is vast when I first see it. In west Irasburg, the Black River snakes north in tight curls. Today, the river is cordoned off by a forest of young sugar maples and yellow birches throwing shade on the surface current. Summer corn fields rise clean out of the ground in sharp relief, dark green and if you look closely enough, a faded pink where the stalk meets the earth. At the fields’ edges: large and looming barns. But it was vaster for Jack and Anne.

There was more and there was less.

Imagine the corn falling back into the earth, the soil, fissured by yearly plantings, sealing itself into a uniform expanse of pasture and hay. Watch the maples draw their leaves back and shrink into saplings, then into seeds in the riverbank silt, laying bare the sweeping apostrophes of the river’s past meanders. Turn back time, and the land flattens, leaving an infinite set of uninterrupted horizons from where you stand.

It was the May of 1975. The nights were crisp and wet with spring rain; the days were mellow. Jack and Anne scaled these Vermont hills in two trucks. One, Jack’s old pickup, the other, a hulking farm truck—1937 Chevrolet, one of those with the bulging fenders over 50-inch wheels, a dark teal and patched together with a body they had found at a junkyard. The back was packed with antique farm equipment—old horse harnesses, a hammer mill, a rotary tiller—wedged in tight with the rest of their belongings: a wringer washing machine, a treadle sewing machine, and more.

They had bought all of this at Amish farm auctions in Wisconsin, where Anne had just finished college and Jack had gone to join her, hitchhiking across New York state and riding buses through “the dregs of all those Midwestern cities.” It took almost a week to drive across to Vermont, passing through the upper peninsula of Michigan, up into Sudbury, Ontario, where Jack remembers coming down a hill pumping the worn-out brakes and barely stopping. Across northern New York and slipping through Hazen’s Notch, a narrow mountain pass in the northern Green Mountains. And then they were in Irasburg, the choice of this town almost arbitrary if it weren’t for some friends who were renting out a little house and a little barn. They were here in search of a past, and these lands seemed to offer it up. It had this mystique, Jack tells me, something he couldn’t quite describe but places in the juxtaposition of farm and forest.

Jack and Anne pulled into their house in Irasburg, a few miles down a dirt road. In a few days, they would buy a cow, a small Jersey, and name her Pet. That summer, Jack planted six acres of flint corn. Raccoons destroyed the crop that summer, but it was the beginnings of what would become a 40-year journey in growing grain that would culminate in a 400-page book of advice. Few grow their own grain—it’s been mostly left up to the large wheat and corn farms out west where growers buy new seed each year from the usual lineup: Cargill, Syngenta, Bayer. As people grow more interested in local food, mostly produce, grain has been slow to fall into step; for Jack, it was a key to self-sufficiency.

He had first encountered grain-growing a few summers before at a 19th-century historic farm-museum in central Massachusetts, harvesting rye by hand with a reaping hook, a knife that curves violently into a sharp question mark. Jack and Anne had met here, too. Jack had dressed in costume—a vest, a shirt ballooning at the wrists, a straw hat—and guided visitors through a panorama of New England life in the early 1800s. Anne wore a costume, too—a bonnet, a dress with ruched sleeves and a pleated skirt. Leather boots, too, for the both of them, although neither were convinced boots were that nice back in the day. Old Sturbridge Village is a charming place, replete with covered bridges and horse-drawn wagons, a snapshot of time brushed in veneer, the toiling standard of 19th-century living chamfered away.

When Jack first told me about Old Sturbridge, I imagined a collection of buildings lived in, abandoned, then made new again by a history enthusiast. But Old Sturbridge Village was never a real village. Born in 1872, its mastermind Albert B. Wells had in the later years of his life become fascinated with the trinkets of post-revolutionary America. He had by 1935 accumulated so many items—hand-smithed tools, frail painted porcelain, weathered book plates—as to fill his mansion in Southbridge, Massachusetts and then two barns beyond. When that was not enough, Wells and his brothers purchased an old farm by a ruffled stretch of the Quinebaug River in the late 1930s, and commissioned a landscape architect to build new 19th century buildings—“authentic” was a key word—going so far as to order old mills and barns be plucked from elsewhere and arranged on this patch of land into a fictional swatch of history. 9

At the time of Wells’ fanatical interest in things of the old, industrialization had long paved the road out of self-sufficiency, and farmers no longer grew food for self-sufficiency but for markets brought to their doorstep by railroad. Beginning in the mid-1800s, fields of oat, wheat, rye, turnips, potatoes, were slowly uprooted and replaced with single crops destined for burgeoning urban markets.

Even before Old Sturbridge, Jack had carried an idealized vision of self-sufficiency. When he was a student at Tufts University, he had read Helen and Scott Nearing’s Living the Good Life, subtitled How to Live Sanely and Simply in a Troubled World. The book chronicles the retreat of a couple from New York City into the central folds of the Green Mountains at the height of the Great Depression. Here, removed from urban life, the two of them erected a rigorously self-sufficient model of rural living. A stone and timber house, built in a rough patch of overgrown forest. Inside, exposed hand-hewn rafters and wood-paneled walls. Floors made of stone. It was not an adoption of rural ways already present in 1930s Vermont, however, but of a life pegged to earlier, seemingly unsullied, panels of time. Vermont in the 1930s, let alone in the 1970s when Jack and Anne came, had already been so thoroughly animated by human activity for thousands of years and in more recent history bound to the flows of commodity agriculture, a marionette contorted by invisible strings.

This landscape of open fields and forest saw its first iteration with the mass migration of white settlers to Vermont in the late 18th century. In the decade following Vermont's admission to the union in 1791, the population nearly doubled. Forests were rapidly cleared to make way for farmland. Early on, the trees were girdled; a strip of bark would be hacked away from the base of each tree in a narrow ring. Over several years, the roots would wither, cut off from the sugars made in the leaves. In later years, the trees would just be felled and left to dry over the winter. The land cleared faster this way.

The logs would be sent down river to become lumber or burned to make potash, a chemical compound that'd be leached from the ash in big wooden vats. Even then, Vermont was overlain with pathways of global trade: the potash would be exported to England for use in its growing textile industry. For most settlers, the additional income went toward paying off the land.

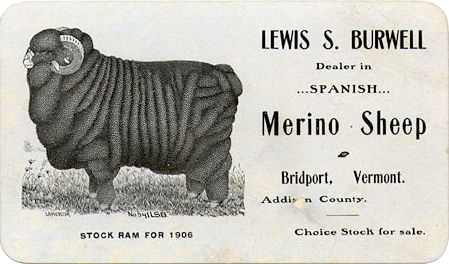

The arrival of Merino sheep brought more trade to Vermont. Valued by the Spanish for their thick wool, Merinos soon replaced the English breeds that had been mostly raised for mutton.

By 1820, the wool industry became the main and most profitable industry in Vermont.

Under high tariffs, the Vermont wool industry thrived.

In 1835, there were 6 sheep to every person.

Native grasses were replaced with high-nutrient European varieties that are still used today as dairy feed—timothy, orchard grass, red and white clover.

And just like that, the sheep kept the hills bare.

Due to their proximity to urban markets, Vermont farmers enjoyed a competitive edge in the wool industry in the early 1800s.

Map: Wool Produced per acre

But the connection of the Ohio and Erie canals a decade earlier would begin to erode this advantage.

In 1840, the Erie Canal carried 100,000 pounds of wool east, mostly produced in the Ohio Valley.

In 1845, 3 million pounds of wool shipped on the Erie Canal.

The cities were growing. Clothing factories were looking for cheap wool.

In the flat plains of the Ohio River Valley, farmers expanded their herds, all the while feeding grain that was much less costly to produce out West.

The price of wool fell.

--—1850—--

--—1860—--

--—1870—--

As wool production migrated west, a new industry spread out across the rural Northeast. Women in cities had begun to feed cow's milk to their infants, spurred on by social reformers, and left without the wet nurse networks that characterized motherhood in rural 19th century New England.

In cities, the social relations that had facilitated shared breastfeeding unraveled. Dairies popped up in ccities—usually "swill dairies", operations attached to distilleries that supplied fermented mash as feed for the cows. 10

Although the railroad became a viable means to transport milk in the 1840s, it wasn't until the late 1800s that the dairy industry spidered into the countryside. Swill dairies, usually foul and unpleasant operations, were outlawed. That, coupled with ballooning urban populations and rising land costs, necessitated the market's expansion. 11

--—1900—--

--—1920—--

But even as these pastures were excavated from maple forests standing centuries tall, even as this grass was then groomed by cows that made milk that was then trucked to cities, an image of secluded wilderness nonetheless stood in for Vermont. Of the people, the Nearings write, “They were as removed from modern civilization as if they had been born in some remote Alpine village. We had crossed a wide chasm when we moved from downtown New York to this isolated spot.” The Nearings came to free themselves of economic weights, to “make it more difficult for civilization to impose restrictive and coercive economic pressures.” Jack and Anne came, because of this: “We were damned if we were going to be part of the capitalist system.”

They stayed in Irasburg for a year, and then they went looking for land of their own. It was the last week of May in 1976. They knew what they’re looking for. Not land on a steep side hill—that’s bad for growing grain—and the soil needed to be well-drained, wet enough for plants to grow, but not so wet that they will drown. They rounded the corner onto a dead-end road and they see it: grassland as flat as a pancake, oh so green with a spray of yellow early-summer dandelions. Anne had 20 thousand dollars of her family’s money squared away for graduate school. They bought 60 acres of this land.

In a few years, they would have built this house, where Jack and I now sit. Wooden beams hold the ceiling and walls, a warm brown, knotted in some places and flecked in spots with termite holes. We’re in the living room, a tight space, Jack in his recliner, me on the couch where the cloud-filtered morning sun has poured a soft haze onto the gray-blue fabric. The dialysis machine clicks a few times, as though it is shifting gears, and then the whirring starts up again. A few feet away in the kitchen, Anne is preparing a fish chowder, pulling bags of frozen filets from the freezer and leaving them in the sink to defrost. Every now and again, she ties on a yellow medical apron and comes by to check on the machine, punching at buttons through a face mask she had worn earlier and chiming in on Jack’s story.

“The organic dairy industry has kept evolving,” Jack is saying. “And I’ve always felt that we have been ahead of the curve. It just comes with being a pioneer, I think, or something.”

Anne cuts in.

“Well no, you got some influence early on. There were people that studied a lot about alternative agriculture and stuff like that. Right in the area,” she says. “How would you sum up what”—somebody, I don’t catch the name— “had to offer? He was really into the soil.”

“No, he was much more minerally based, I think,” Jack says.

“That’s true.”

“We were the first people to build a bedding pack barn for cows,” Jack continues.

“We weren’t the first ones.”

“Yeah, we were the first ones in dairy!”

“Nope.”

“Yes, we were!”

“Jersey Girls. We went and visited them before.”

“Okay. Jersey Girls. Hers was a lot different.”

Anne cuts in again, talking over Jack. “And then there was that one over in Sutton.”

They go back and forth for a few more seconds and then Anne laughs. Jack smiles.

“Glad you’re here, Anne,” I say.

“She keeps me humble, you know?”

And then after chatting for a while, Anne pulls off the medical gear and heads back to the kitchen, sometimes stopping by the food dehydrator next to the dialyzer to grab a tray of something—pumpkin seeds, mostly, on the days I visit.

The kitchen island is spilling over. Plastic yogurt containers, bowls of spare change, an old juicer, a candelabra coated in wax hardened mid-drip, dusty brown bottles of essential oils. A small corner is left bare for cooking.

When Jack and Anne moved here, they brought three of their cows along—Pet, and her heifer, Nutmeg, and hers, Sundance.

“You gotta breed these cows to have them give milk,” Jack says.

Three became six, became 12, became too much milk.

“The nature of cows,” Anne says from the kitchen.

They began making yogurt on their wooden stove, wide with heavy circular panels that they would lift to pile in split logs from the top. These days, it’s all done mechanically, the cultured milk poured into plastic containers and then pushed into an incubator to sit. But back then, the milk would be poured into a cream separator, into the wide metal bowl up top. One of them would crank the handle. It would be hard to get started, and then the crank would pick up momentum, and the machine would get louder and louder until it was a high-pitched buzz. They’d turn a lever to let the milk flow into the spinning chamber, where the heavier skim milk would flow to the outer edge, and the cream would gather in the center. And then out of one spout would come trickling pale-yellow cream, out of the other, a ghostly stream of skim milk.